Not every battery can claim to have won a Nobel Prize, but the lithium rechargeable battery can. Winning the 2019 Prize for Chemistry, the rechargeable lithium battery is ubiquitous. Today it powers nearly everything, from smartphones to electric vehicles. Perhaps more than any other device, the rechargeable lithium battery has fuelled the technological revolution of the 21st century.

Yet, like everything, this comes with a cost. The battery is a physical device and it requires physical resources. In this case: the precious metal lithium. With the help of Visual Capitalist, we look at how the battery works, how our current use and extraction of lithium is unsustainable, and which SET100 start-ups are innovating to ensure we can still use the lithium battery to power our lives as well as the energy transition.

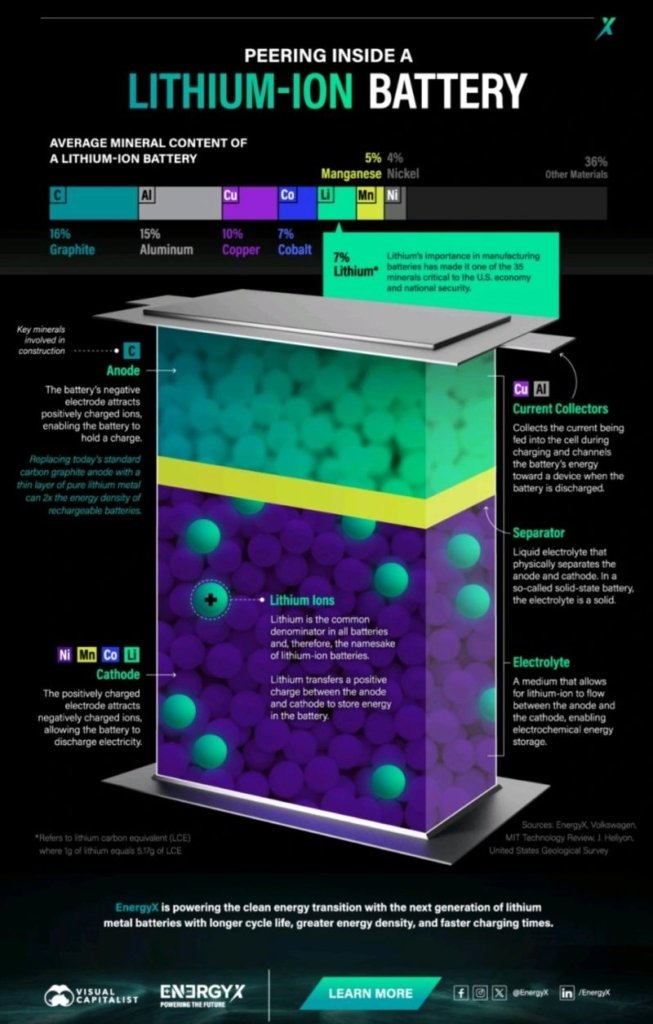

How Lithium Batteries Work

Work on rechargeable batteries goes back to at least the 1950s. But it wasn’t until the 1980s that more effective prototypes were developed. These used lithium. American chemists M. Stanley Whittingham and John Goodenough both made early strides but it wasn’t until Akira Yoshino in 1985 that the first prototype of the modern lithium battery was developed. This was then commercialized by Sony and Asahi Kasei led by Yoshio Nishi in 1991.

Lithium is not the only precious metal that is present in the batteries. As lithium-ion cells can be manufactured to optimize energy or power density, various rechargeable battery types use a combination of other metals to develop different properties, such as refined Manganese (currently priced at $2,225 per metric tonne), Copper ($9,140/t), Nickel ($26,751/t), refined Cobalt ($49,902/t) and Lithium Carbonate ($78,009/t).

Handheld electronics mostly use lithium polymer batteries (with a polymer gel as electrolyte), a lithium cobalt oxide (LiCoO 2) cathode material, and a graphite anode, which together offer high energy density. Meanwhile, lithium iron phosphate (LiFePO 4), lithium manganese oxide (LMR-NMC), and lithium nickel manganese cobalt oxide (NMC) may offer longer life and a higher discharge rate. NMC and its derivatives are widely used in the electrification of transport.

Supply & Shortfall

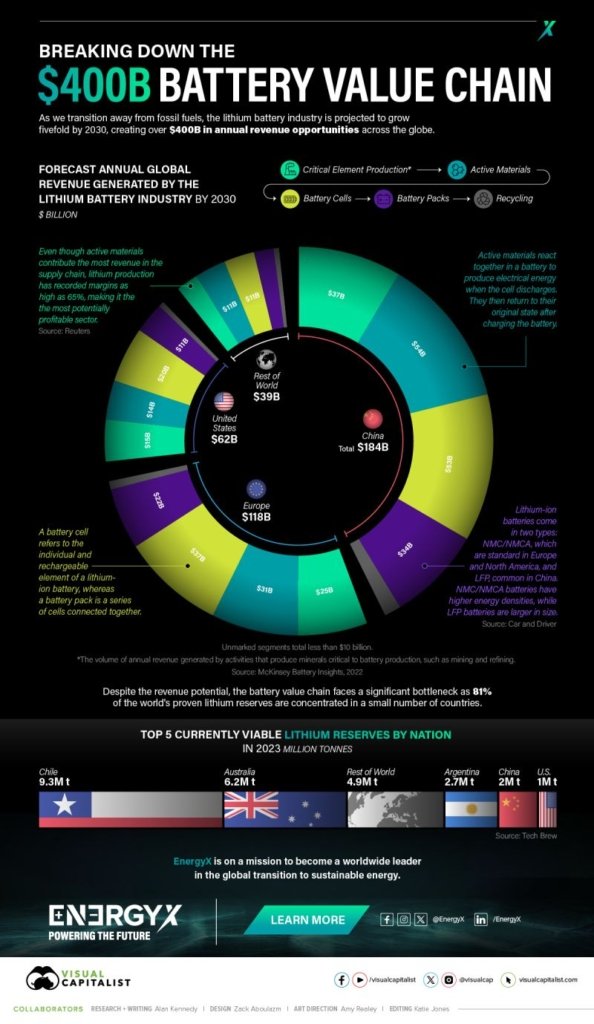

China dominates the refining of most battery metals and accounts for 78% of global cathode production. The country also has lithium reserves of about 2 million metric tonnes. This is compared to the US with 1 million tonnes, Argentina with 2.7 million, Australia, 6.2 million. However the world’s largest estimated reserves are located in Chile, which has reserves of 9.3 million tonnes.

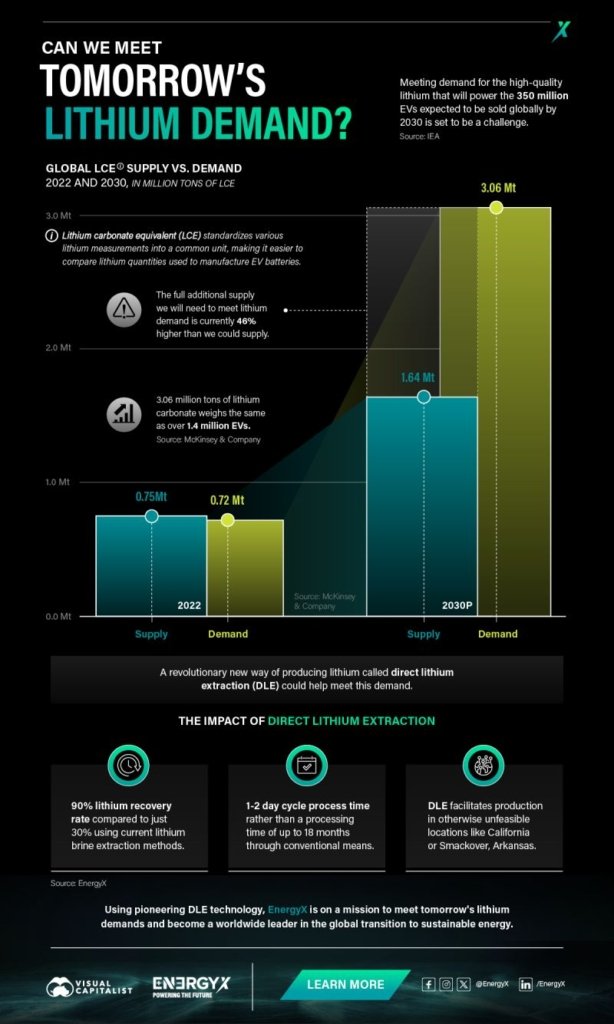

With so many uses for the metal, it is perhaps unsurprising that demand is soon to outstrip supply. According to research by McKinsey and Company and Visual Capitalist, by 2030 there will be a 46% shortfall, if current projections and demands for new technologies are met (for example with EVs).

The problem is not just the metal itself, but how it is refined. Current extraction techniques, such as brine or pyrometallurgical extraction methods, are woefully inadequate, recovering only around 30% of the metal. This, combined with a lack of infrastructure that can reuse and recycle old lithium batteries, has led to calls for change before it is too late.

Innovating Lithium-Ion

So, what’s the good news? Start-ups across the globe are already scaling up innovative solutions that promise a sustainable energy storage ecosystem and cleaner alternatives. Among them are of course a number of SET100 trailblazers.

Green Li-Ion & Li-Cycle

These two start-ups are at the forefront of the battery recycling revolution. Green Li-ion‘s ‘deep clean’ technology is revolutionizing the regeneration of lithium-Ion batteries, not just restoring battery life but also reclaiming high-purity materials for future energy storage solutions.

At the same time, Li-Cycle‘s “Spoke & Hub Technologies” are converting battery waste into indispensable, battery-grade materials, ensuring these resources serve new purposes in powering our future.

LeydenJar Technologies

The Netherland’s LeydenJar Technologies is propelling the potential of energy storage with their patented pure-silicon anodes, which significantly enhance energy density. This leap forward ensures batteries last longer and charge faster, substantially reducing carbon emissions and production costs.

VoltStorage

VoltStorage leverages the potential of the underdog of battery tech: redox flow system. These systems break away from the constraints of conventional lithium-based technologies, providing a resilient, scalable, and eco-friendly energy storage alternative.

These three SET100 start-ups are not only addressing the challenges of lithium supply they’re also helping transform the energy storage ecosystem. By deploying technologies that foster a circular economy and curtailing further raw material extraction, they also help shrink our ecological footprint and ensure the energy transition can continue. The question is: how quickly can we scale these solutions to meet demand?

For more insights and tech know how from us and the wider industry, be sure to follow us on LinkedIn, Twitter or We Don’t Have Time.